Introducing Tips In Machinery Designing

Rightly said, “Drawings are the language of design engineers”. For all the people associated with the quality manufacturing, drawing becomes the backbone of their business starting from creation of any part or assembly to the modification task of the same. CAD platforms are becoming inevitable during the engineering design. Many CAD platforms are available in the market to choose from. CAD drafting is as important as the product when it comes to modular design. Modular design is the call of today’s manufacturing industries as market is so demanding and every new design or innovation gets obsolete in a short span of time. Three points are being reflected from the above discussion,

- 2-D and 3-D CAD Drafting

- Modular and Efficient machine design

- Design modification and optimization

Experience, Dedication, Technology based solution should be the main parameters upon which any of the CAD service provider can be finalized.

Some deliverables by CAD outsourcing firms:

- Scan/ Paper to CAD Conversion

- 2D to 3D CAD Drafting Conversion

- AutoCAD 2D/3D Drafting

- 3D CAD Drawings

- Fabrication Shop Drawings

- Manufacturing Drawings with BOMs

A Pharma machinemanufacturing firm had design legacy of 2D drawings in non-editable format hindering design alterations. By partnering with Scripturient India engineers, 2D drawings were converted to part and assembly drawings in CAD to improve turnaround times.

What are fabrication drawings?

Types of Fabrication Drawings

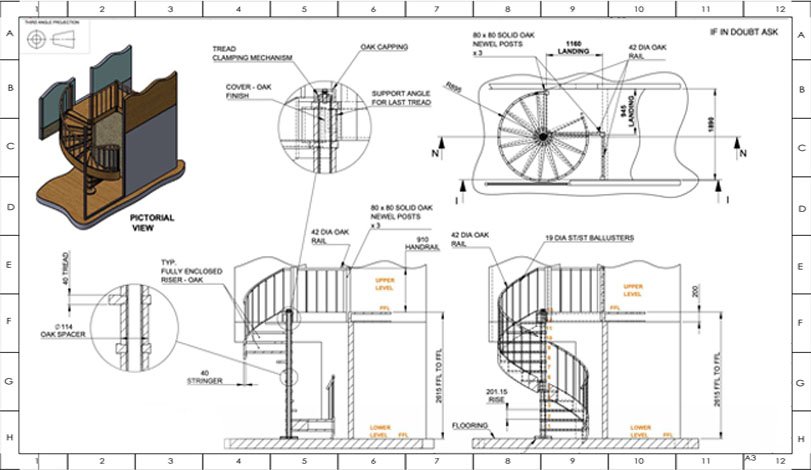

Fabrication drawing, per se, is the umbrella under which many sub activities to be covered separately. These sub-types starts from standalone parts or components to the assembly of multiple such components. In that way designer pass through the various drawing stages like part drawing to assembly to complete layout and so on.

Types of CAD Drawing important for fabrication

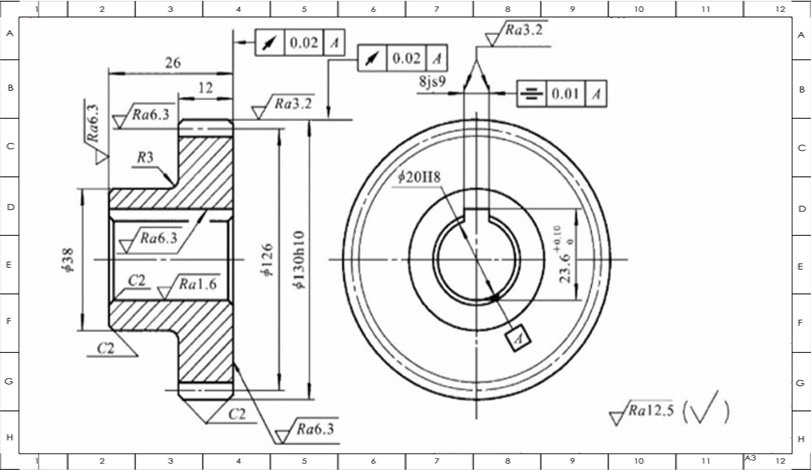

Part Drawing

Part drawing is the separate drawing prepared for the individual part. These drawings also includes the technical information about that particular part like material from which these part going to be created, overall dimensions of the part, weight of the part etc.

Assembly Drawing

In contrast to part drawing, assembly drawing includes information about how each part is going to be fit into the assembly. These drawing covers the tolerance information too in the assembling of each part. In this drawing, part detail with material information also covered in the form of “Bill of material” (BOM). In short, assembly drawing represents the complete machine information. Many a times, production drawings are also gets considered in this category.

General Arrangement Drawing

As the name suggests, General arrangement drawing (GA) focuses on the arrangement or the process that is going to be followed to realize the assembly from multiple parts. General arrangement drawings are also in varieties according to the industries and processes.

Why are Fabrication Drawings Important?

Given the purpose it serves, fabrication drawings have importance right from manufacturing, assembly and installation stage. But it has more benefits. Let’s take a look.

5 Advantages of Fabrication Drawings

Visualization of large assembly from different angles.

Cohesiveness in manufacturing.

Safer fabrication and hazard free operation.

Ease in decision making for various operations like welding, cutting, drilling etc.

Detailed information on manufacturing instructions and tolerance in assembly.

What is 2D fabrication drafting?

Even today, field experts deliver 2D drafting using a variety of CAD conversion services using various CAD softwares. It is easy to convert conceptual designs and hand-drawn sketches, PDF files and paper drawings to CAD while following international standards and code requirements such as ASME and ANSI.

Converting 2D fabrication drawings to 3D CAD drawings/model

One of the most outsourceable task in design and drafting is the 2-D to 3-D CAD conversion projects. Reason for this outsourcing is also convincing because 3-D model enables the client to see the product exactly how it would look once it is built. Through the 3-D model, designer can demonstrate how all the parts fit together and how the final machine or product reacts after assembly. Proper fit and tolerances can be visualized well in 3-D CAD Models. Review on design fit can avoid the design flaws before freezing the design for final manufacturing.

Expertise and accuracy in the 2-D to 3-D conversion is quite important. Errorless conversion is the only motto for this task and that could be possible only with the trained and experienced taskforce. CAD service provider like Scripturient India can deliver this task with accuracy and integrity with their dedicated technical teams.

How to identify the right fabrication drawing service provider?

At the outset, it is essential that the CAD outsourcing company you hire is familiar with international drawings standards likeISO, ASME etc. and standard techniques to accomplish the task with quality and within the timeframe. Field expertise imparts the useful parameter in to the service provider. Team or a Person should be familiar with the various.

Various other aspectslike cross culture sensitivity, Outsourcing business etiquettes and understanding should match up with the client’s expectation.

How can Scripturient India consultancy help you?

Accurate and onetime design and drafting solution is the call of today for manufacturer as well as fabricators. Qualitative drawings keep the fabricators safeagainst fluctuating market demand.

Such CAD services help fabricator or manufacturer bring down the lead time for their product or plant deliveries as well as increase in customer satisfaction for their quality deliverables. Technically sound and field expert team at Scripturient India aim to bring qualitative change in industrial designs through our design, drafting and analysis service.